Markets

INDUSTRIES IN FOCUS

Cortus replace fossil fuels in industries where it is most needed.

STEEL INDUSTRY

The steel industry accounts for about 11% of Sweden’s total CO2 emissions, and 7% of global emissions, making it one of the largest CO2 emitters. The forecast for 2050 is that the demand for steel will increase further due to a growing population and urbanization. Cortus can replace fossil fuels within the steel industry and reduce its climate impact.

Hydrogen

One way for the steel industry to become more sustainable is to replace coal with hydrogen within the steelmaking process. However, established production processes for renewable hydrogen are very energy demanding. The Cortus end-product has a high hydrogen content (60% H2) and can easily be upgraded to pure renewable hydrogen (100% H2).

Energy Gas

A big initiative for the steel industry to become more sustainable is the Probiostål project. The aim of the Probiostål project is to replace natural gas with Cortus renewable energy gas. Read more about the project here.

Biocoke

The major carbon dioxide source in the steel industry is fossil coke (coal). In order to minimize the carbon footprint, fossil coke can be replaced with biocoke within the steel making processes. Cortus biocoke has shown a great potential for replacing fossil coke and is now investigated further, read more here.

TRANSPORT

The transport sector stands for 30% of the total greenhouse emissions in Sweden, whereas the majority comes from road transport. In Sweden, the goal is to reduce the greenhouse emissions with 70% (compared to 2010) by 2030. New innovative solutions for producing renewable transport fuels are required. Cortus unlocks several possibilities for generating renewable liquid and gaseous transport fuels.

Biogas

Cortus end-products are ideal to be further refined into biogas for which infrastructure and vehicles exist. This has been proven in pilot scale, read more here.

Sustainable Aviation Fuel

Sustainable Aviation Fuel (SAF) is a clean substitute for fossil jet fuels. Rather than being refined from petroleum, SAF is produced from sustainable feedstocks. For commercial application there are six different technology platforms that are certified for SAF production. Within these platforms Cortus end-products are needed, hence Cortus has a great potential within the SAF industry! One pathway for production of SAF using Cortus technology was investigated in 2019, read more here.

Fuel Cell

Fuel Cell Electrical Vehicles (FCEV) are powered by hydrogen and eliminates the weaknesses of electrical cars: short range and slow charging. However, established production processes for renewable hydrogen are very energy demanding. The Cortus end-product has a high hydrogen content (60% H2) and can easily be upgraded to pure renewable hydrogen (100% H2).

OTHERS

The challenge to decrease the fossil dependency is also big within other sectors, such as power and chemical production. The composition of Cortus end products makes them suitable for sustainable chemical production as well as power production via a gas engine (or turbine).

Combined Heat & Power

The majority the world’s power production is based on fossil fuels. The share of renewable power is increasing but it needs to accelerate. Several of the renewable initiatives are weather dependent, which is an issue for creating a stable grid. To convert waste to power by incineration results in a low yield. Cortus technology is a weather independent solution with high yield that unlocks the potential for using waste to generate renewable power.

Chemicals

Cortus end-products are also excellent feedstock to be refined into biodiesel, ethanol and other liquid fuels. Our end-products can replace fossil fuels directly, enabling the petrochemical industry to become fossil independent.

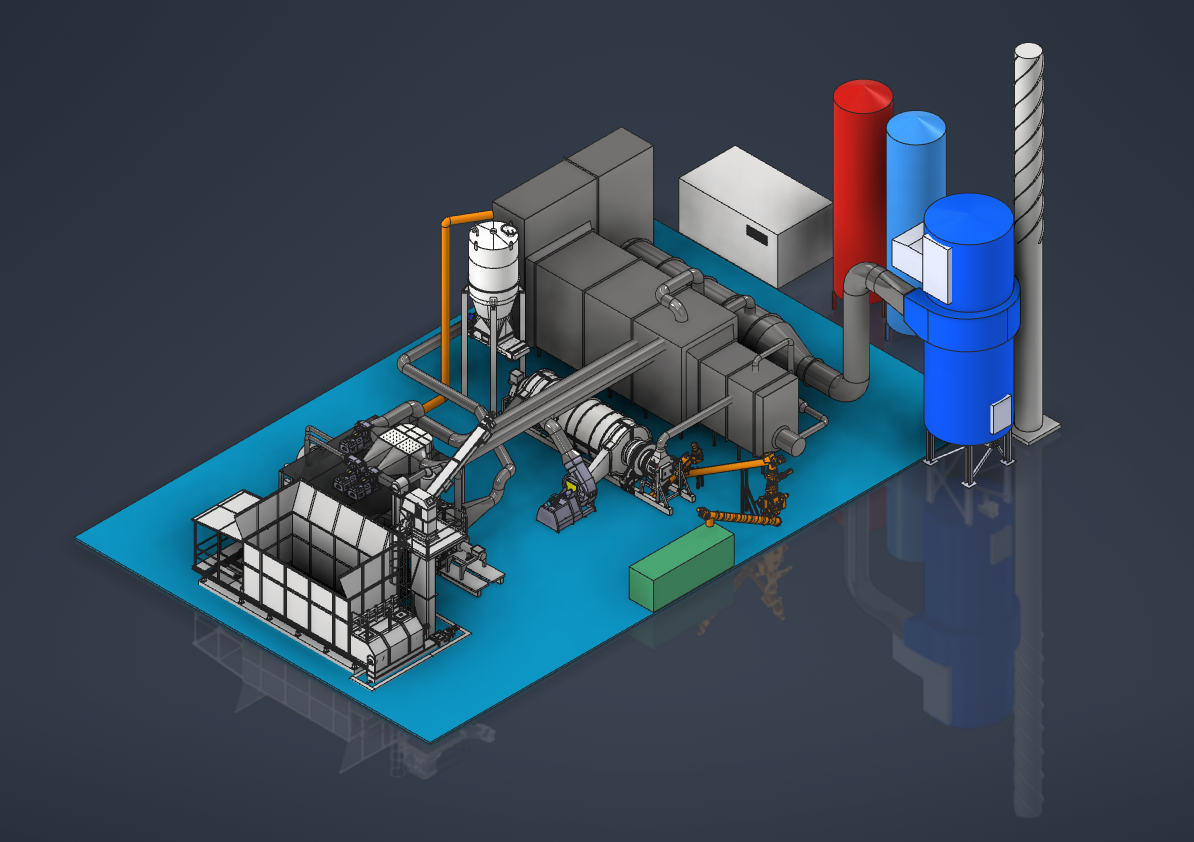

WoodRoll® for biochar – PyroRoll

Customers comes to Cortus with ideas on new applications for the WoodRoll® technology. One such application is biochar. Biochar is a product for soil improvement and decarbonization. Gardening residuals and rest streams are processed to biochar in a pyrolysis process after being dryed.

The WoodRoll® technology is versatile and can be used for biochar production. The typical feedstock of green waste usually don´t have the thermal stability for high temperature gasification as in WoodRoll® for syngas. Instead we can utilize the first two process steps of drying and pyrolysis with a new multi combustor. Hot gas for the dryer and pyrolysis is generated in this combustor. Further, the combustor can incinerate the surplus of pyrolysis gas for further heat treating of biochar or district heating.

A PyroRoll solution for 60 tons per day of green waste is now ready for the market. The solution is based upon Cortus 6 MW WoodRoll® in Höganäs.