2020-09-15

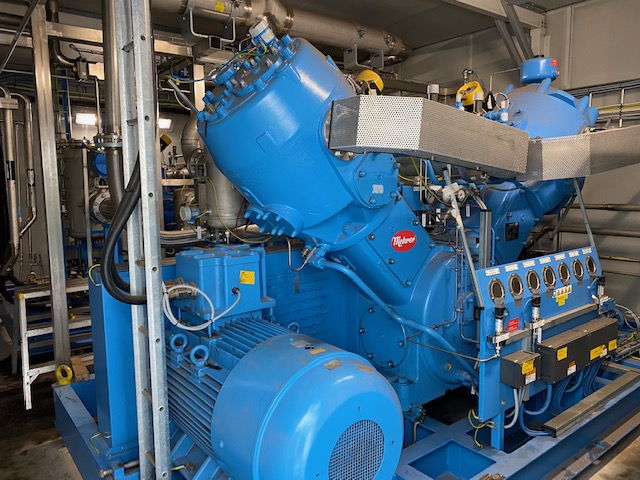

During the first part of September, the compressors have been taken into operation with syngas, which is a major step forward. Capacity tests has corresponded to the requirements for Milestone 3 (MS3), and we will do additional testing to secure reliability. The compressor start-up has worked out smoothly together with the German compressor supplier.

The syngas production has been based on char produced in Höganäs, which is the first time for us, and the quality of the syngas has been according to our expectations. Deficient sealing on the pyrolysis reactor has temporarily stopped char production, and thereby gasification. However, the sealing has been replaced by now and the pyrolysis reactor has been repaired and restarted. Further improvements on the pyrolysis reactor have been implemented for improved availability.

Issues with flaring off pyrolysis gas have been a constraint during the last testing period, but measures to fix these issues are now implemented. Testing has started and is followed by different operational steps where pyrolysis gas is being combusted in all systems, maintaining safe flaring of pyrolysis gas. As soon as these operational steps have been fulfilled, the pyrolysis process is ready for the MS3 run.

The drying system has also been in operation during the month, with longer runs matching the capacity required for MS3. This means that the capacity and operational time for the drying system corresponds to the requirements for MS3, which makes it the first system ready for MS3 operation!

Senaste kommentarer